R45 PCB Motor

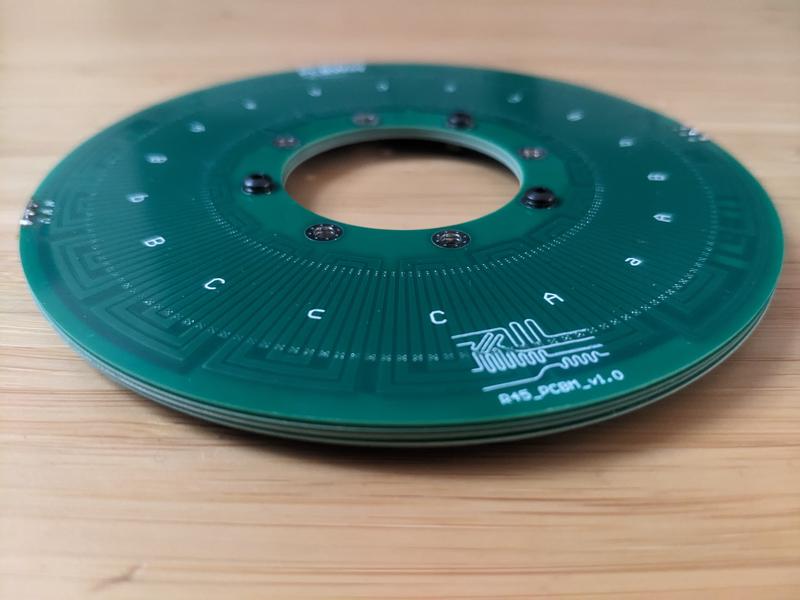

The R45 PCB Motor is a new modular PCB motor concept that allows tuning of performance by simply selecting a different stack of motor PCBs.

This approach combines compactness, flexibility, and scalability in a way that is not possible with conventional BLDC motors.

Motor Design and PCB Technology

The motor is specially designed for current handling and thermal performance. Each PCB can operate as a standalone motor or be stacked in series or parallel configurations to increase power output. This modular design enables engineers to configure a motor according to their application requirements.

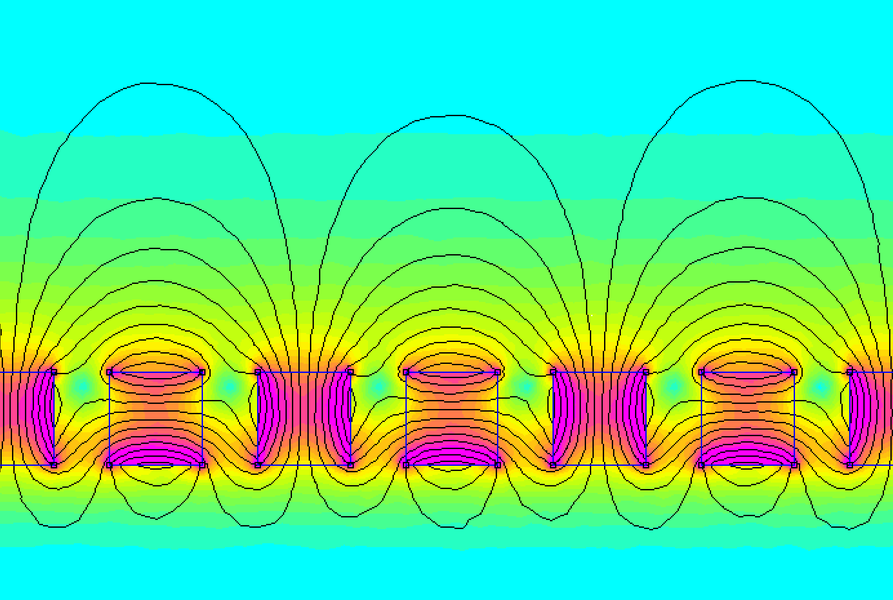

Halbach Magnet Configuration

The R45 PCB Motor uses a Halbach magnet array, which offers two main advantages:

- Concentration of the magnetic field on one side, similar to having a back iron but without the additional weight.

- More uniform magnetic field distribution, even when using standard rectangular magnets instead of expensive arc-shaped magnets.

This design reduces material costs while maintaining high efficiency and performance.

Validation of the Magnetic Design

Once all magnets were assembled, the field distribution was inspected with a magnetic viewing film. The results confirmed that the Halbach configuration behaved exactly as predicted by simulation, validating the design approach.

Electrical and Thermal Performance

When multiple boards are stacked, the torque increases almost linearly with the number of layers, while the thermal performance shows only moderate degradation. For example, with four stacked boards, the thermal performance is only degraded by 15%, additional measures such as thermal pads between layers could further enhance performance.

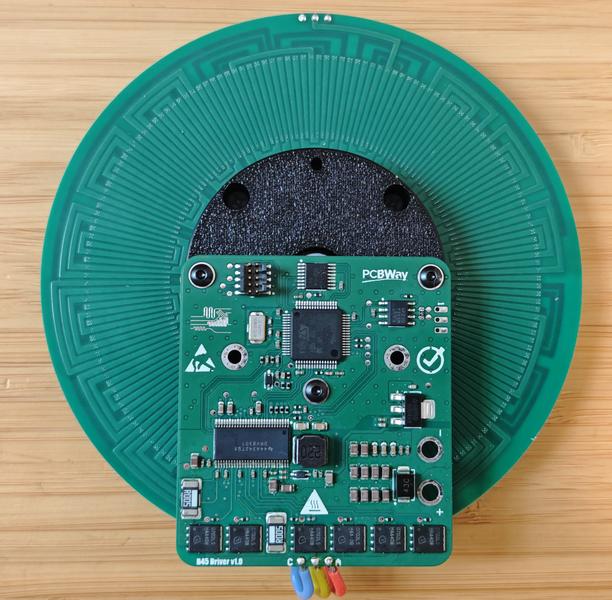

Integration with the R45 PCB Motor Driver

The R45 PCB Motor has been successfully tested with the R45 PCB Motor Driver, demonstrating smooth operation and efficient control. This combination provides a fully integrated motion solution designed around PCB-based motor technology.

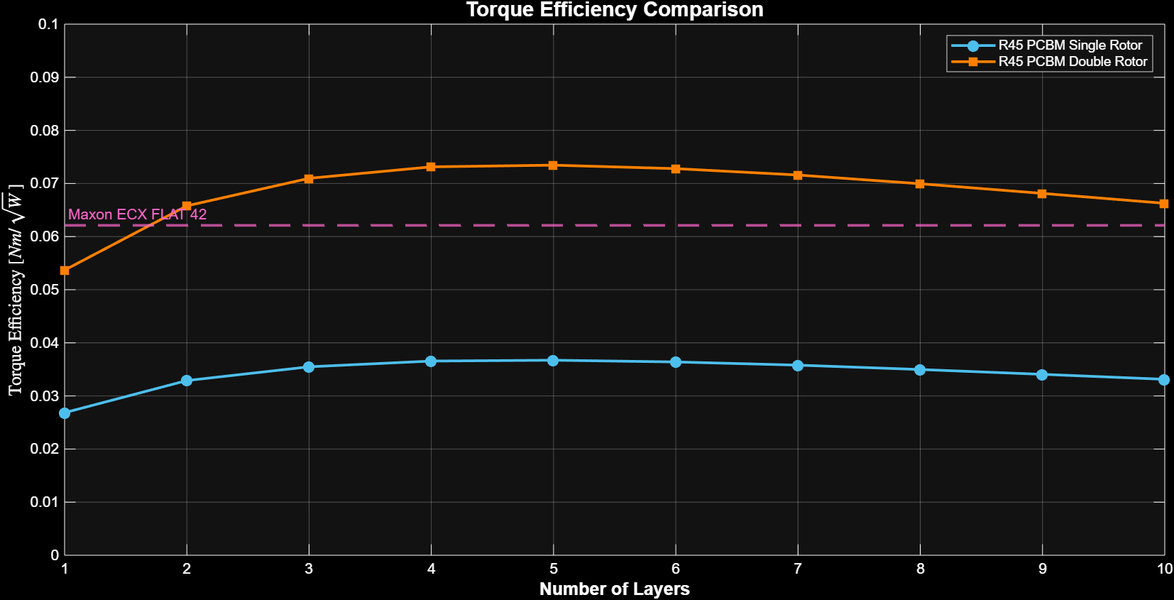

Performance Comparison with Maxon ECX FLAT 42

To evaluate the performance of the R45 PCB Motor, we compared it against the Maxon ECX FLAT 42, a well-known industry reference for compact flat BLDC motors. The comparison is relevant because both solutions share a similar volumetric footprint, making them natural candidates for the same application space.

Why Torque Efficiency (Km)?

The comparison is based on the torque efficiency metric, also known as the motor constant (Km), measured in Nm/√W. This figure of merit combines both torque output and electrical input, providing a normalized way to assess how effectively a motor converts electrical power into mechanical torque.

A higher Km value means the motor delivers more usable torque for a given input power, which directly translates into better efficiency and reduced thermal load.

Results of the Comparison

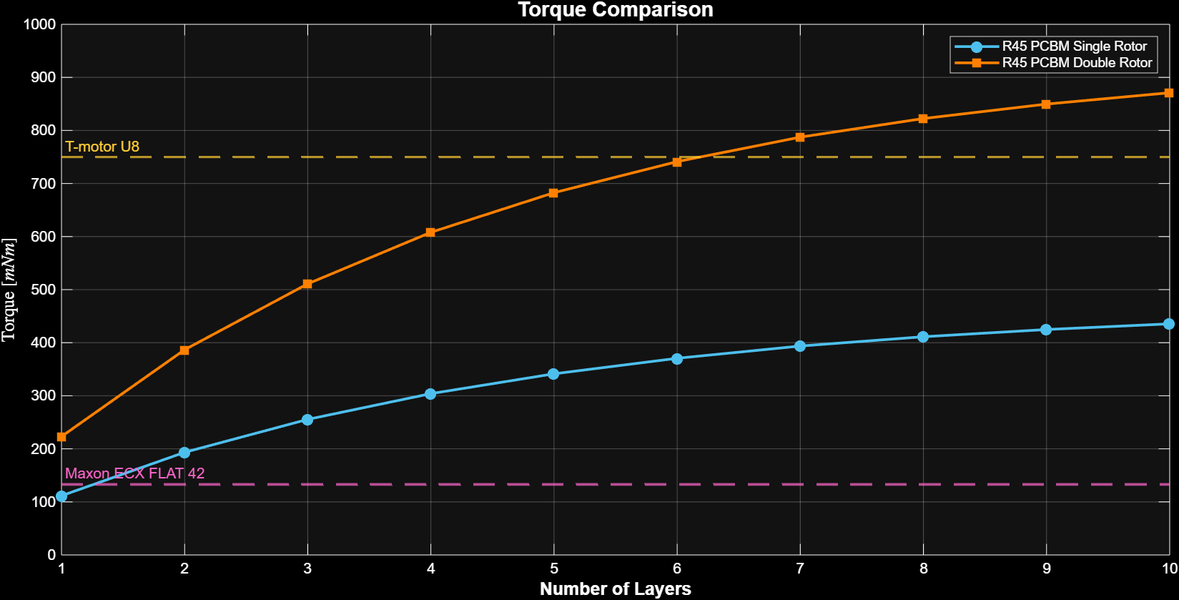

The results show that as the R45 PCB Motor is scaled by stacking additional stators and rotors, its torque efficiency increases significantly. Starting from 2 stacked stators with 2 rotors, the R45 PCB Motor achieves higher torque efficiency than the Maxon ECX FLAT 42.

In addition to superior efficiency, the R45 PCB Motor demonstrates a considerably higher rated torque, reaching values comparable to the T-Motor U8, a benchmark in high-torque UAV applications.

This comparison highlights how the R45 PCB Motor not only matches but surpasses established flat BLDC solutions, while retaining the unique benefits of a modular, PCB-based design.

The R45 PCB Motor represents a new approach to modular motor design, where performance can be tuned by simply adjusting the number of PCB layers. Its compact form factor, efficient Halbach configuration, and seamless integration with the R45 PCB Motor Driver make it a powerful solution for applications requiring flexibility, performance and low cost.